For home & industrial compostable products

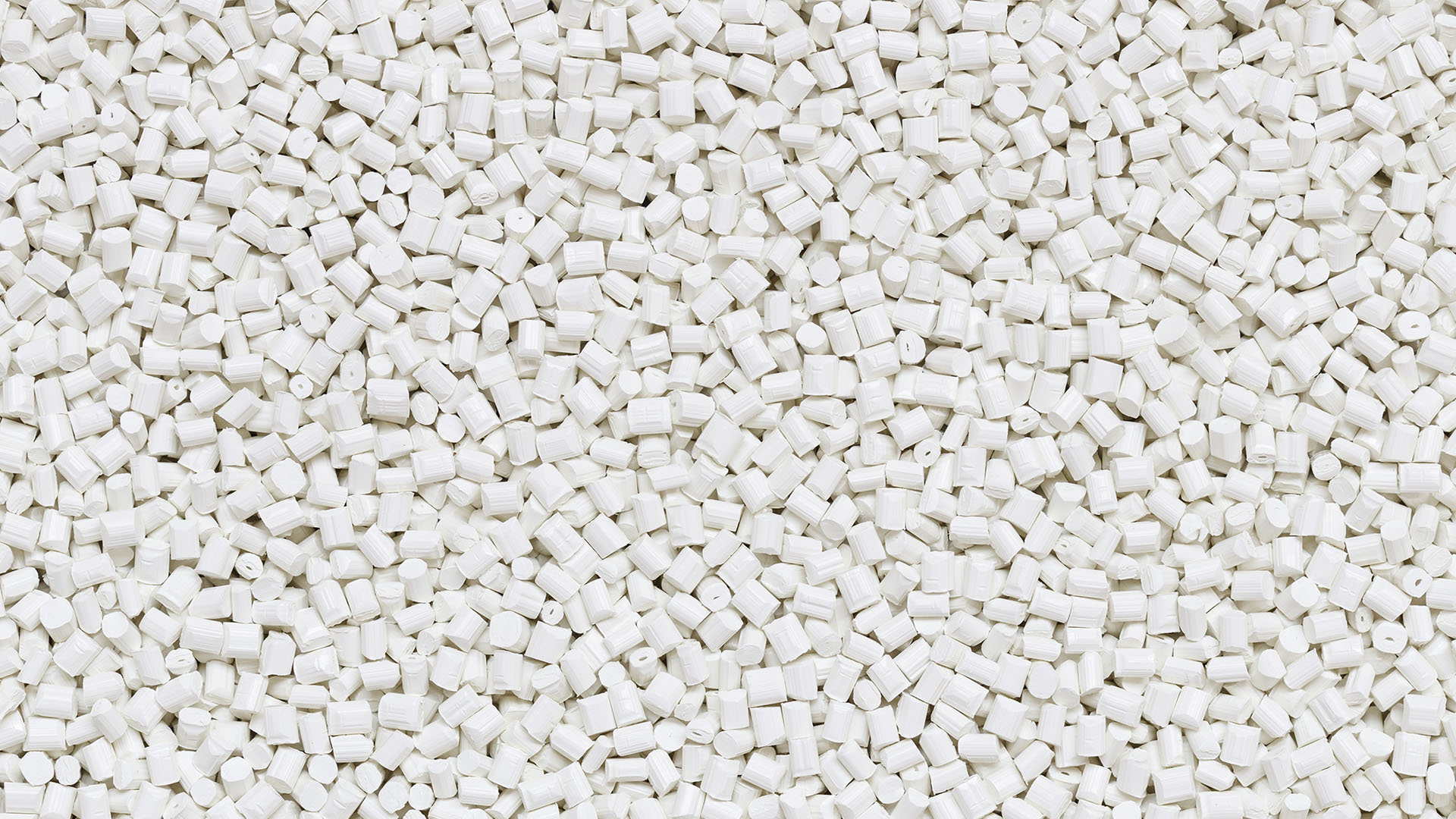

Pragmatic and sustainable alternative to plastics

Speak to our experts, let’s build a sustainable future together

Looking for the right sustainable solution may not be an easy task. We are happy to support you with the material selection, processing, product engineering, mould development, part manufacturing and provide clarifications about our materials.

Latest Media – News, Events & Blogs

Plastic alternatives that matter the most

Plastic Alternatives that matter the most Plastic is one of the major causes of environmental pollution - on land, in the oceans and in our atmosphere. With [...]

Best Plastic Alternatives for the Packaging

Best Plastic Alternatives for the Packaging It is very well-known fact that plastic is one of the most used packaging materials. With an ever-growing population and fast-changing [...]

5 Alternatives to Plastic Cutlery You should know

5 Eco-friendly Sustainable Alternatives to Plastic Cutlery Plastic cutlery has been around for decades, but its environmental impact has only recently come under scrutiny. [...]